#1 Reason Why You Should Start a Pressure Washing Business

Why You Should Start a Pressure Washing Business

This article is for anyone who’s ever thought about how to start a pressure washing business.

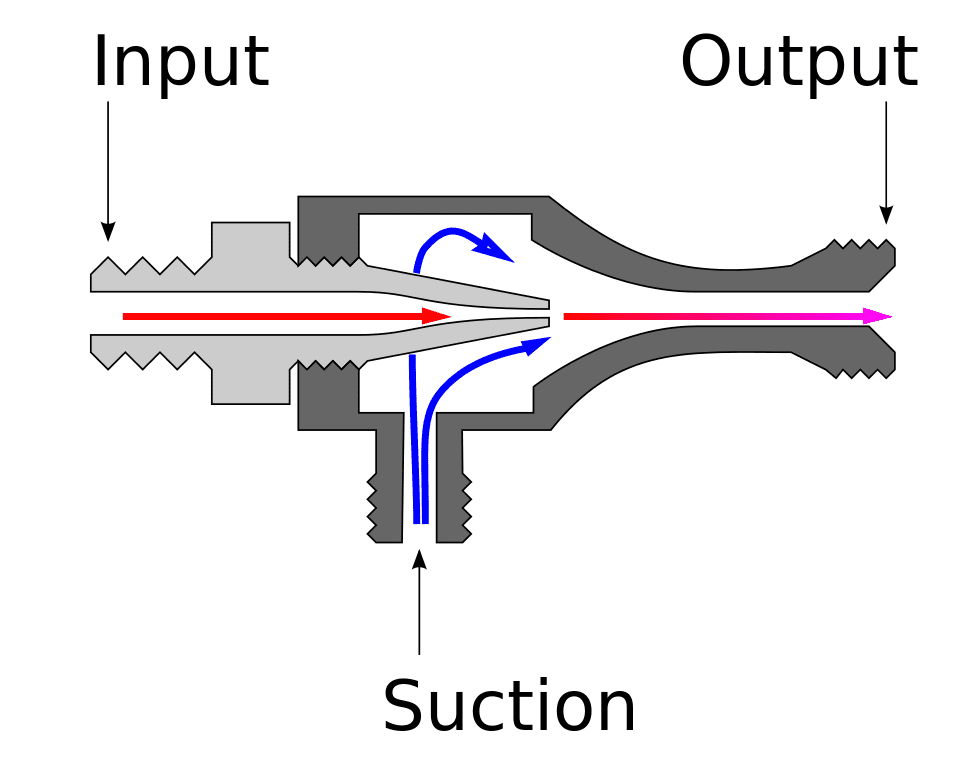

While pressure washing is a commonly-used term that most people recognize, it’s often difficult to find someone to wash your car, boat or house when you need it done. Soft-washing is another common-used term used mostly among pressure washing professionals. Homeowners are becoming more familiar with it, however.

Basically, it’s applying a detergent at a low pressure to eliminate the risk of damaging to a home using high pressure. The cleaning agents do all the work removing the environmental contaminants.

If you have the skills to pressure wash residential or commercial properties and are looking for ways to earn extra income, starting your own pressure washing business could be the right move for you. Even if you lack the skills, it’s very easy to learn. Before you do so, however, it’s important to consider the following three things before you start a pressure washing business.

3 reasons why you should start a pressure washing Business

1) Demand for pressure washing services is growing 2) It’s easy to set up a business these days and startup costs are relatively low 3) The market is wide open for competition. Let’s take a deeper dive into each one.

#1: Demand for pressure washing services is growing with so many homes and businesses needing their sidewalks, roofs, driveway, walls and more cleaned off, there are opportunities abound.

#2: While you may need some special training to get started the invest in high-quality equipment can be as low as a $2000 to $3000. This is considering you already have your own truck. You can start on a shoestring or go all-in and build a extremely capable pressure washing rig.

#3: Competition is a good thing! That means there’s a market for pressure washing services. Your goal is to over-deliver on your value proposition to make the competition a non-factor. If you do that, the competition will be asking themselves “what happened to all my customers?”.

How to start pressure washing

What do you need to start a pressure washing business? To access the easy button, click this link to access my course on “How to Start Pressure Washing Business“.

The first step to starting any new business is to figure out if it’s something you would like to do and more importantly, is it profitable. If you don’t have pressure washing experience, there are plenty of books, YouTube videos and websites that will teach you how. The SBA has plenty of resources that will walk you through the steps of planning, launching, and running a pressure washing business.

Do i need a license to start a pressure washing business?

Many people think you need a contractors license to start this type of business but I’ve found that it’s not necessary in most cases. You’ll have to check your individual state to make sure but in Virginia there is no requirement.

The best time to start pressure washing is now

While the pressure washing industry is not (yet) as saturated with competitors as some other industries, it’s still growing. According to one source, the global pressure washer market size was estimated at USD 1.88 billion in 2019 and is expected to reach USD 1.95 billion in 2020. Another perk?

Where can I find customers for my pressure washer business?

To start a pressure washing business you’ll need to do some research to make sure you’re targeting the right customer segment. Where you find your customers will depend upon which business model you decide to start. Conducting primary and secondary research will identify customer segments and help you decide what type of business model to start.

Do you want to focus on the residential exterior home cleaning market or the automotive cleaning / detailing market? Do you want to do commercial work or strictly residential? Each of these is a separate market segment with different needs, wants and profitability.

Where can I find used pressure washers?

If you’re looking to start a pressure washing business, but don’t want to spend a lot of money, then buying used pressure washers is an option. There is more risk with purchasing used equipment, but you can get some good deals if you’re careful. I suggest implementing a strategy to immediately re-invest your earnings into bigger and better equipment.

This shoestring startup strategy is a viable one and through disciplined pre-planned action, is a great one. Check your local pressure washing store for used gear, Craigslist, Offerup, or other auction sites for great deals.

What type of detergents should I use in my pressure washer?

The most common cleaner used in the exterior residential and commercial building markets is Sodium Hypochlorite (SH). The chemicals you choose to use in your pressure washer depend on what kind of cleaning job you’re doing.

If you’re cleaning concrete, make sure to use detergents specifically designed for these surfaces but also the kind of stain you’re trying to remove. If your cleaning job involves soil or other organic or environmental material, you still must consider what you’re cleaning as well as the type of stain.

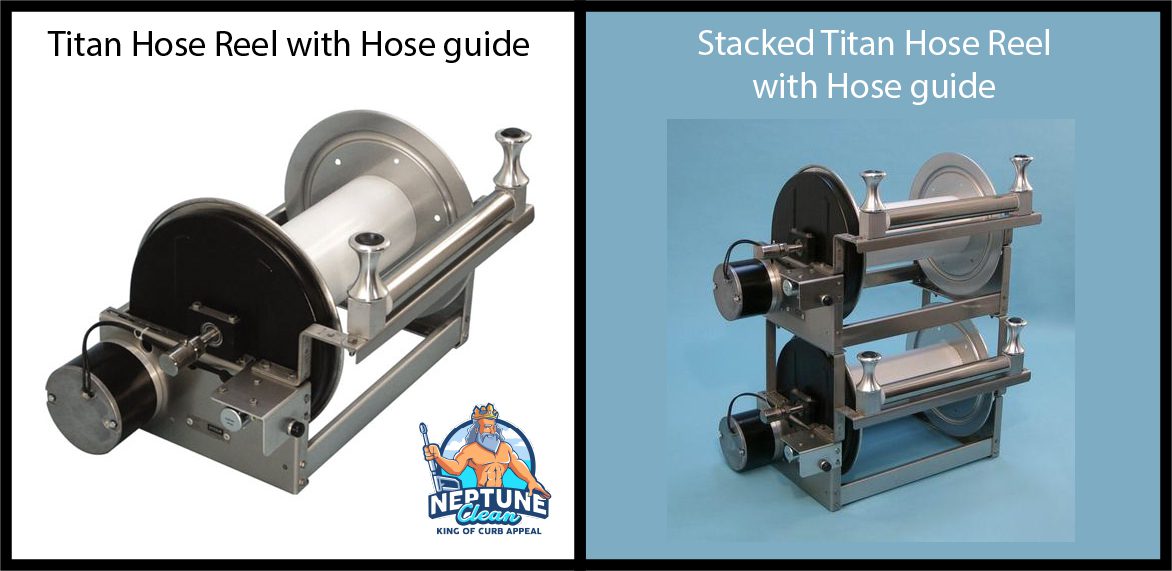

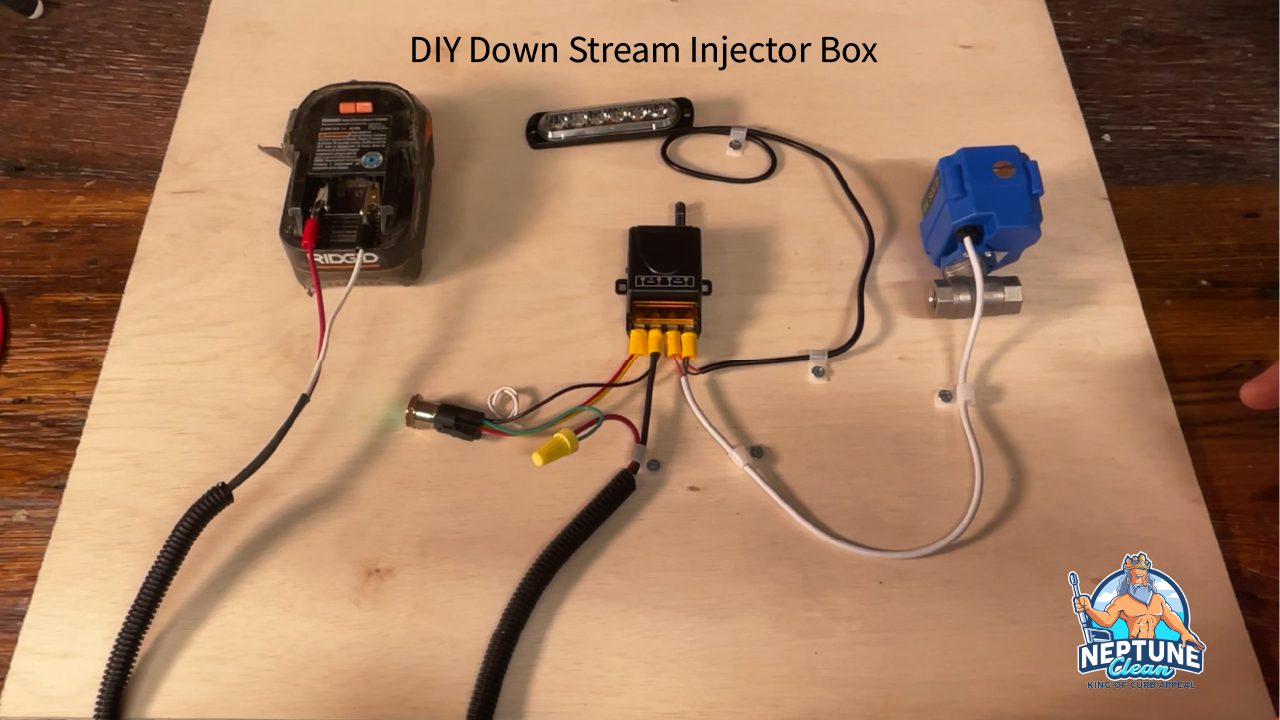

What equipment will I need start a pressure washing business?

Starting a pressure washing business doesn’t require an enormous outlay of cash, but you will need to purchase some equipment—the total cost is dependent on a few considerations. First, you need to think about the business model you’d like to start.

Will you serve the residential market, commercial or both? Will you offer additional services like roof cleaning or window cleaning? There’s many more considerations but these examples require different equipment and therefore, more capital.

How do I get my customers?

Getting customers for your pressure washing business can be tough—especially if you don’t have any money to spend on advertising or building awareness. So, how do you get customers? Here are three great ways to drum up business for your pressure washing company: Attend networking events.

If you meet someone who needs pressure washing done, ask if they know anyone else who might need it done. Go old school and drive through neighborhoods looking for homes that need cleaning. You can leave a doorhanger with a quote on it to clean the home. Better yet, knock on the door and hand them the quote. You might just get the business on the spot.

What if it rains?

Light rain never hurt anyone, so I’ll put on a light raincoat and keep working. If the rain becomes too heavy it will rinse the soap off prematurely so you may have to wait for the rain to lighten up a bit. Pressure washing near me is a season business so we like to take advantage of the time we have and service as many customers as we can.

Can I make money at this?

The great thing about a pressure washing business is that you can choose different business models. I like to think there’s riches in niches so plant your stake in the ground and specialize in the automotive detailing area, restaurant hood vent cleaning, or even window washing.

There are plenty of people out there who make money washing cars, windows, and homes, but can you? As with any business, you’ll need to assess whether it’s a viable option for you. Consider these factors when determining if starting up your own pressure washing business is worth it. I will tell you that I would not be doing this if it was not profitable. That’s what you go into business for in the first place.

How much will it cost me to get started?

How much money you will need depends upon your business model and what equipment you already have. Do you have a truck and a trailer? You’ll need transportation to get you to where your customers are. The customer segment you intend to serve as defined in your business model will dictate the equipment you need and therefor the price.

I would plan to spend anywhere from $1000 to $5000 and more depending upon your resources. A market research study will help you in determining how much money you will need. To start a pressure washing business you can also begin providing services on the weekends until you build up a reputation and enough business to go full-time. If you’ve decided to start a pressure washing business see the Small Business Administration Startup Guide.

Click here if you’d like a quote on pressure washing services